As part of the recent ground developments taking place at Salford City’s Football Stadium, this scheme adds an extension to serve as a bar and changing room for those both visiting the stadium and playing on the pitch.

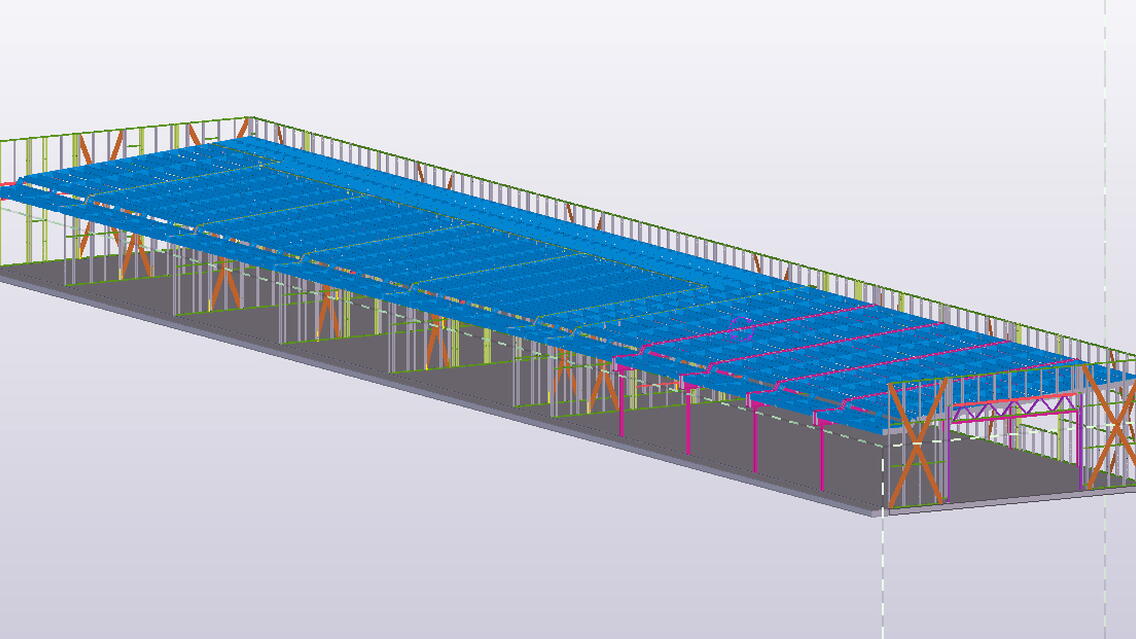

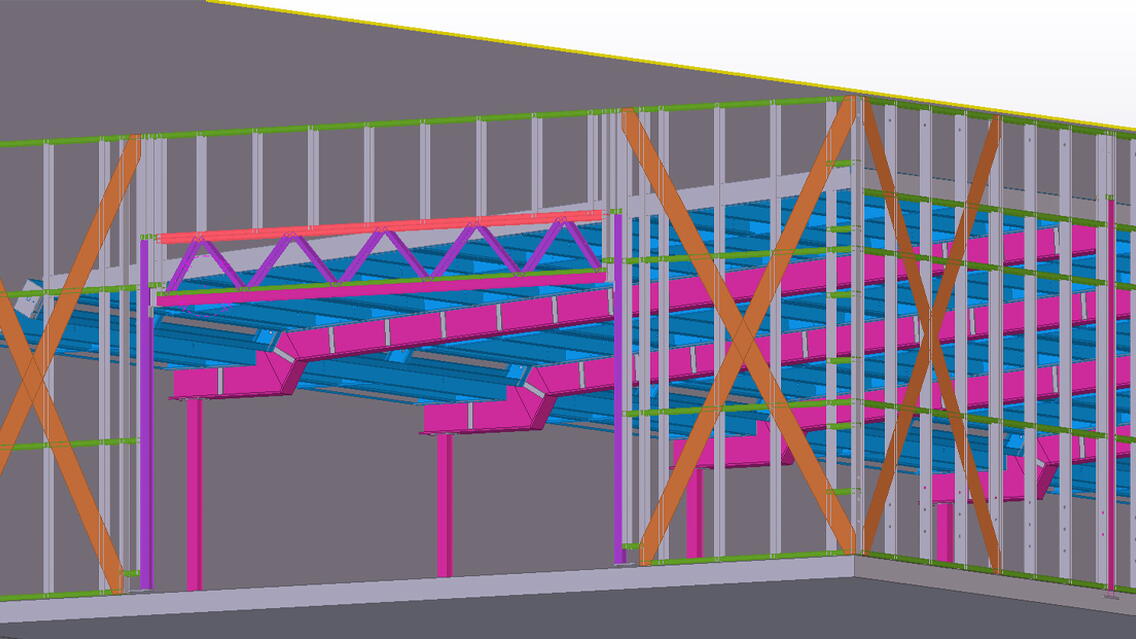

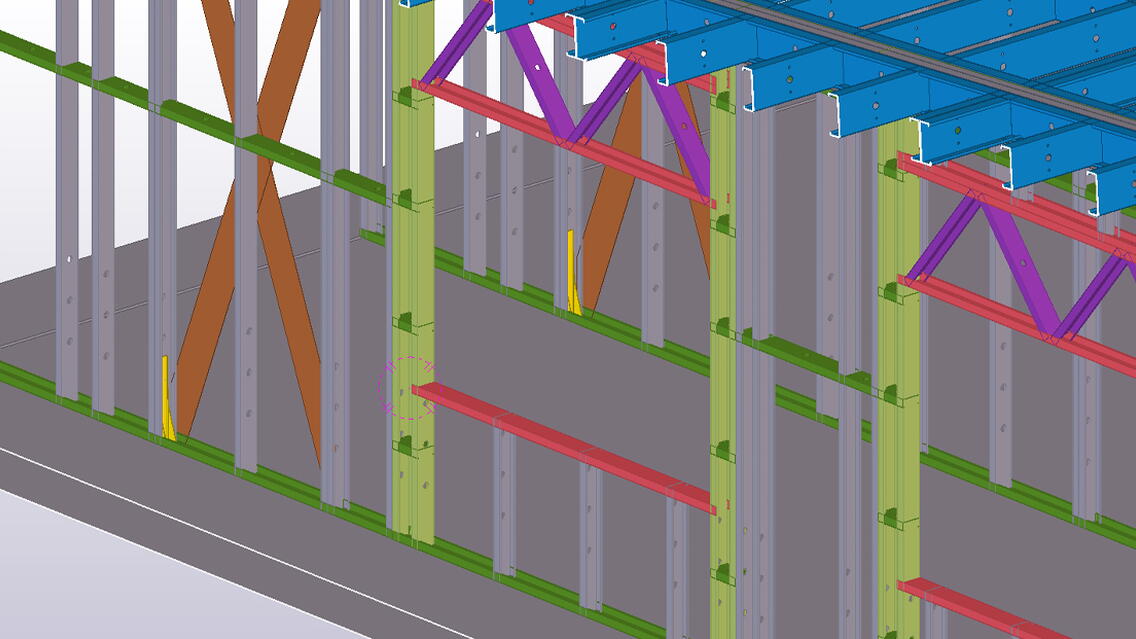

Produced from both light gauge steel and hot rolled steel, the project was designed as pre-panelised frames which demonstrates a modern method of construction and capitalises on the benefits that pre-built panels bring. With entire sections of the building delivered without the need of construction on site, time and energy can be saved to reduce the overall time that workers are required on site.

Situated behind the South Stand seating area, the supporters bar can be accessed via a roller shutter entrance where those who have tickets to see the home side play may purchase refreshments before the game begins. Within the bar is a slotted window with viewing access directly to the tunnel through which the players themselves enter the pitch, all of which is kept dry from the elements via a pitched roof, and all elements of this extension were designed as pre-built panels which ensures that the framework can be installed in the quickest time possible which will in turn reduce the amount of disruption for players and supporters alike as the extension could be erected before the start of the football season.

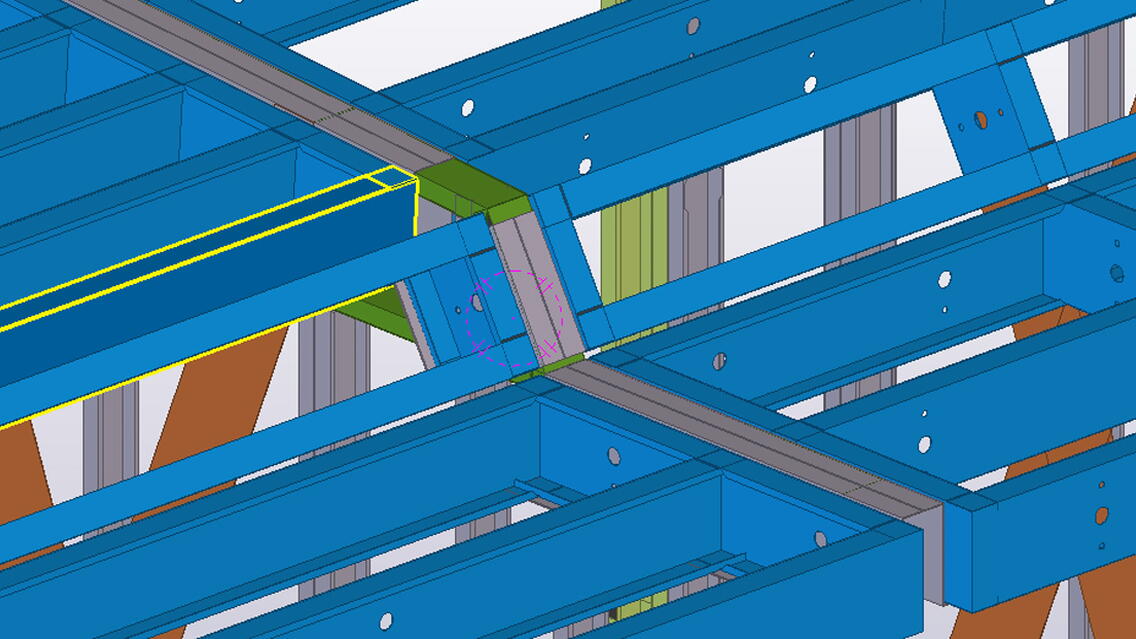

The extension had to work with the already existing stadium, meaning that the roof cassettes had to perfectly join with the pre-existing structure to prevent water damage and keep the interior insulated. This is where Tekla Structures gave us the tools to visually demonstrate to the client and the install team that by extending our cassettes past our walls, we could cut into the insulation of the existing building to close any gaps between the supporters bar and the pre-built stadium. The issue of keeping the interior insulated was of paramount importance with a changing room being included within our scope.

What were the challenges and what made the project successful.

As the design of the extension was not a completely separate building and instead was an addition to an existing building, it was difficult to ensure that the extension lined up with the stadium. With the use of reference models we were able to fully visualise just how the old and new elements would work together to become a completed build.

As the roof cassettes were at a pitched angle, it was as challenge to ensure that all of our frames sat correctly atop their supporting zed plates, however with the use of separate views and work planes we were able to counteract the various angles that the roof followed and provide an accurate design to the client.

What benefits utilizing BIM and Tekla Software brought to the project.

Using Tekla from project inception to create the structure was highly beneficial when it came to delivering accurate models and meeting the client’s brief:

- By importing 2D reference models, the margin for error was reduced. This allowed the design process to flow more easily and ensure the client’s expectations were met with fewer revisions to the design.

- Having the ability to create IFC models enabled quick and easy sharing with the necessary people. This was beneficial as it kept all parties up to date with the current model, enabling effective clash detection and collaboration on any queries or design developments.

The use of Tekla as bespoke 3D modelling software and BIM, married with the use of a bespoke CAD/CAM interface to our roll forming machines, allowed the fully detailed design to be exported straight from design to manufacture. The fully pre-engineered solution was designed, manufactured and assembled on-site with confidence, creating a highly impressive building that exceeded the project expectations of both the client and main contractor.

The project in numbers

Hot Roll Weight: 4.6 Tonnes. Cold Roll Weight: 14.2 Tonnes. Dimensions: 57.5m long x 10m wide x 4.2m high