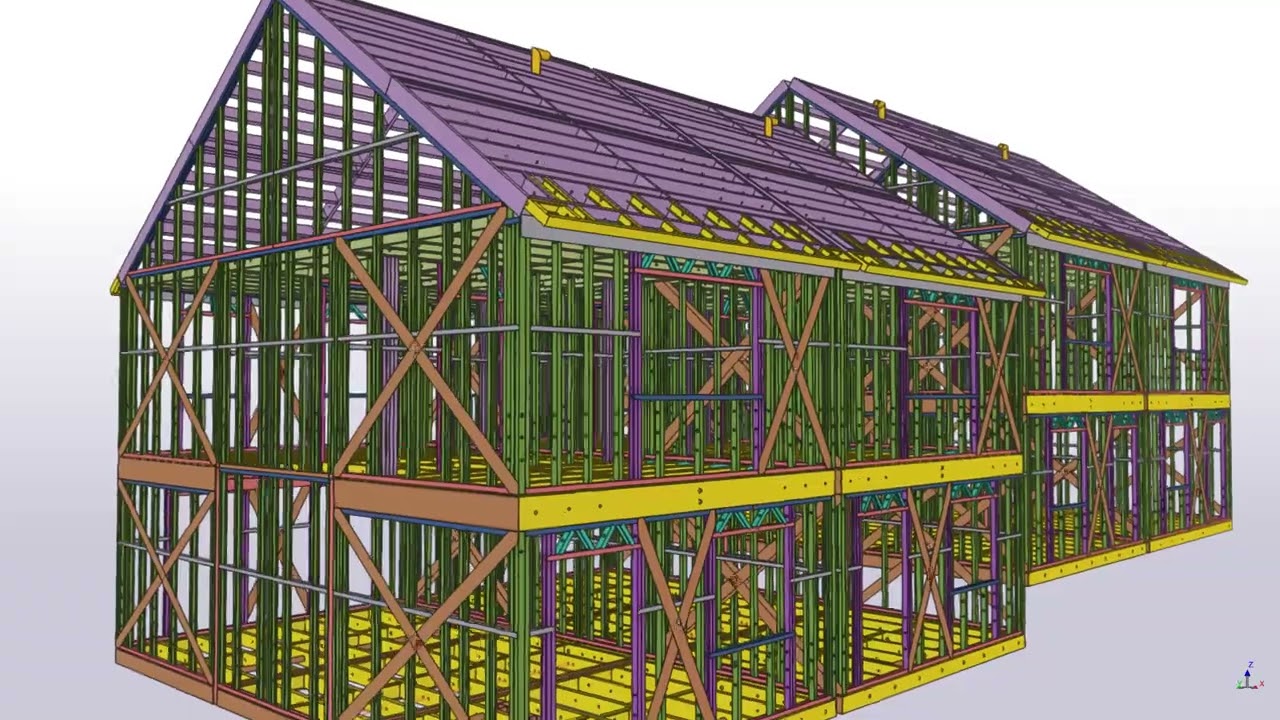

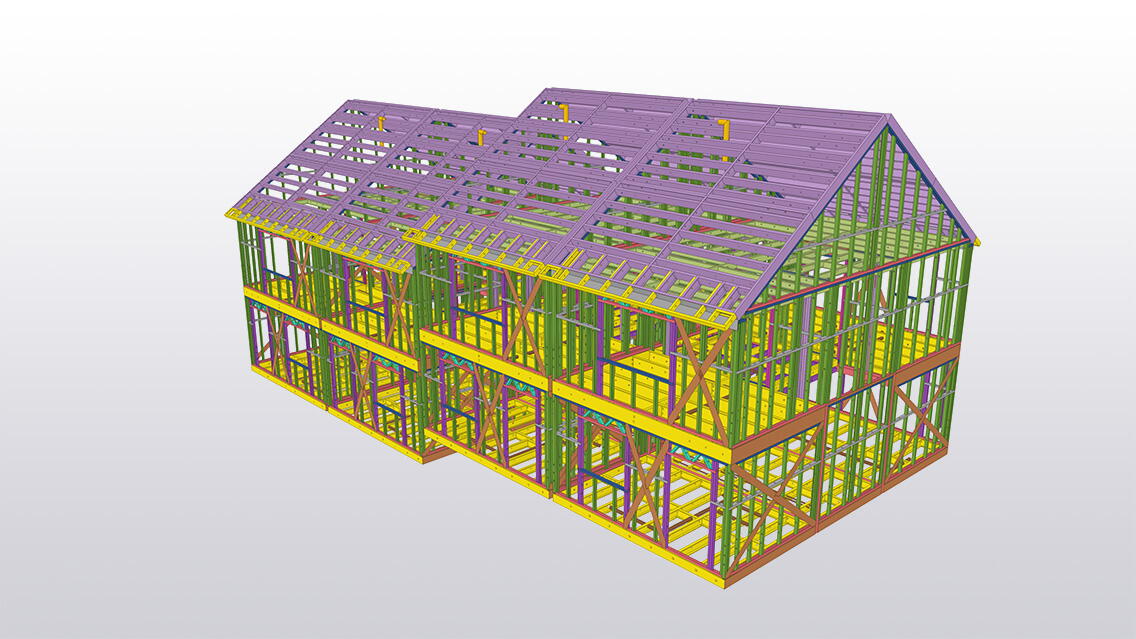

The project designed is a collection of small residential buildings, consisting of 2-bedroom homes constructed primarily from light gauge (as well as supporting hot rolled) steel elements. The construct is semi-modular with the cores of the buildings containing the kitchen, bathroom and stairs; all of which were designed and manufactured off-site. The units were then transported to site in where the rest of the building will be constructed around the central hub of the house.

Challenges and achievements

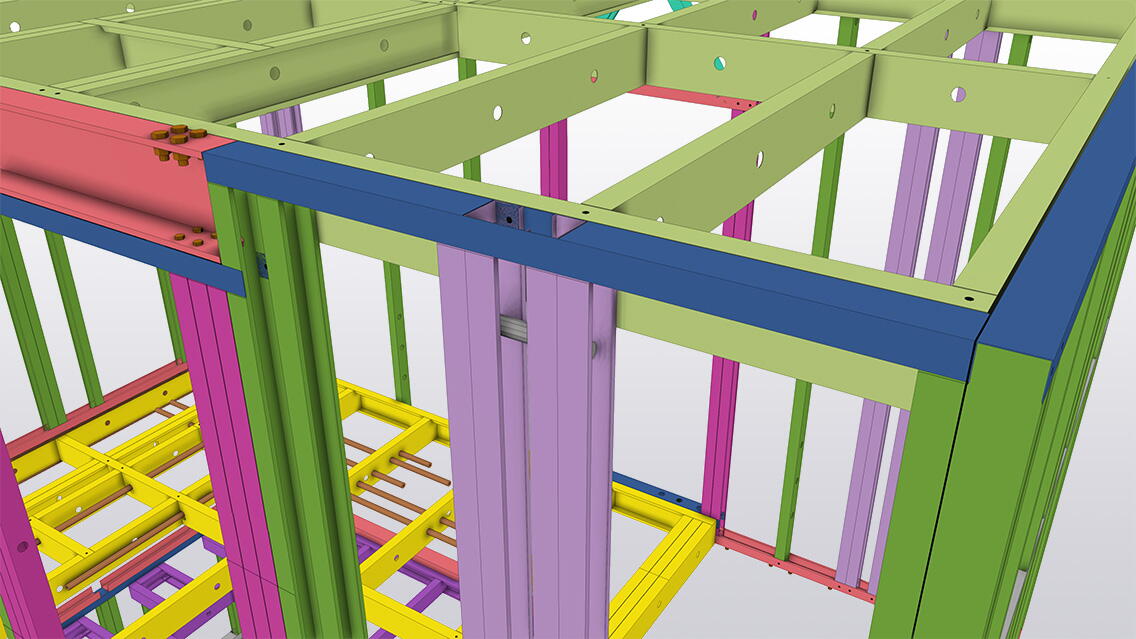

The project undertaken by Frameclad encountered a few challenges primarily during the Research and Development stage. A notable challenge involved the hybrid use of HR Steel and SFS (Steel Framing System) to create the center modules. While standard details like guide pins and lifting eyes could be used for modules solely made of HR Steel, the inclusion of the SFS module required exploring alternative lifting and secure connection methods.

Frameclad's solution revolved around generating pre-punched holes within the SFS studs using a Howick-based macro. These holes facilitated the insertion of pre-fitted guide pins from the HR module below, ensuring proper alignment of the modules. To enable lifting, notches were created through pre-punches, allowing a lifting hook to reach within the SFS wall and connect to a lifting rod fitted within 32mm diameter pre-punched holes, preventing damage to the SFS itself.