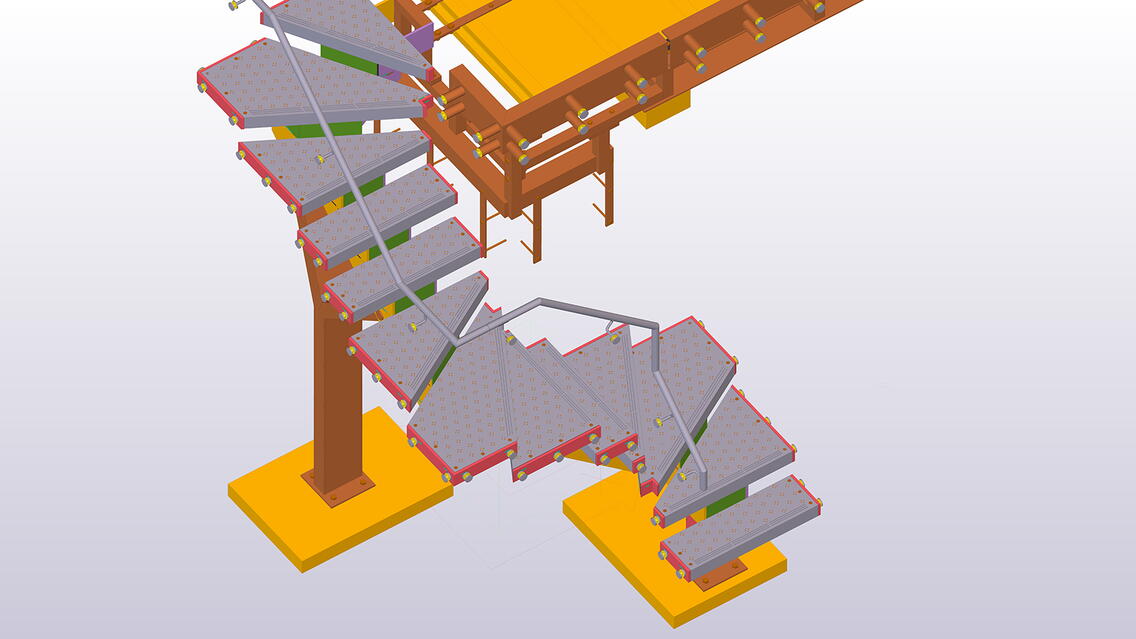

Bespoke staircase for luxury housing extension

TDS Midlands was approached and sent details for a totally bespoke staircase located externally on a luxury housing extension development in Hitchin. The stair required full design collaboration with both the architect involved and the end client.

The only design details supplied called for the staircase to be a 'full winder stair which changed directions three times' and, for the 'staircase to be unique in design and ‘to move away from the traditional way a staircase is constructed and designed’.

An initial design spec was created for the client’s approval prior to the stair progressing from concept to full design development: We outlined the following:

- To move away from traditional flat bar stringers

- Modular in the fixing method

- Low iron glass to be used so that the glass is as clear as possible

- To have stainless steel-formed treads instead of open mesh flooring treads

- Fully integrated drainage system designed in to stainless steel treads to avoid standing water

- No staircase fixings apart from glazing fixing to be visible from the stair elevations

- A tree column feature instead of a standard CHS or RHS columns

- Unique pinning connection for the column connection back to stringers

- No welds to be visible to give clean lines so castellation fabricating methods will be used during fabrication

How Tekla helped to realise this complex stair design

Tekla aided our design for the staircase in the following ways:

- Being able to design a full integrated castellation plate profile system that formed the treads in all directions. Doing this in any 2D drawing package would have taken two or three times longer to draw.

- The ability to use the clash check tool helped to ensure that all the parts had the castellation lining through and that we had all male and female notching parts lining through. This ensured the treads were formed correctly.

- Once the complex modelling had been done, we used the NC / DXF files for the steel and glass to be made by the relevant manufacturers, thus speeding up the abdication process

- It enabled us to provide full design 3D concept drawings / visuals at initial design concept stage for design approval by the client

- To provide 3D fabrication drawings to aid the fabrication process on complex tread design / arrangement.

- The visuals & amp; 3D views that TDS was able to produce on the staircase helped to get planning permission granted for the stair and extension. Part of the procedure was to provide a good representation of how the stair would look. We used the object representation selection tool to make the glass transparent, the stainless steel in a light colour, whilst trying to colour match the RAL colour that was chosen by the client to show how the finished stair / atrium balustrade would look once totally fabricated, powder coated and installed to a finished state.

Without Tekla Structures we would have been hesitant to take on such a complex stair design as a 2D drawing program would not have been able to show any of the problems that we encountered whilst developing the stair drawings for production.