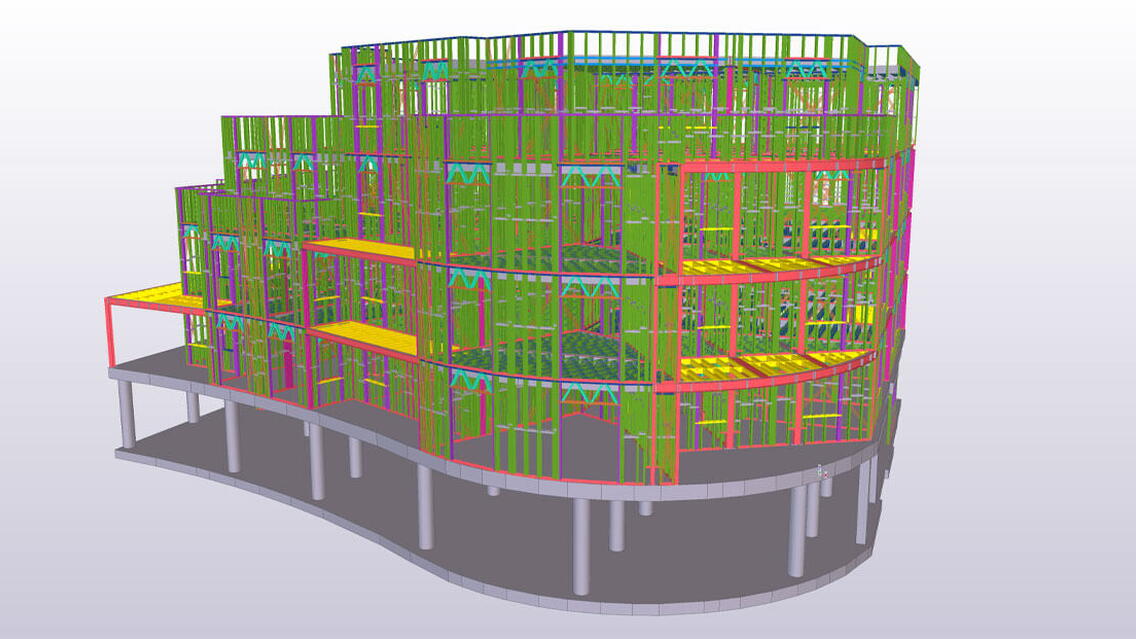

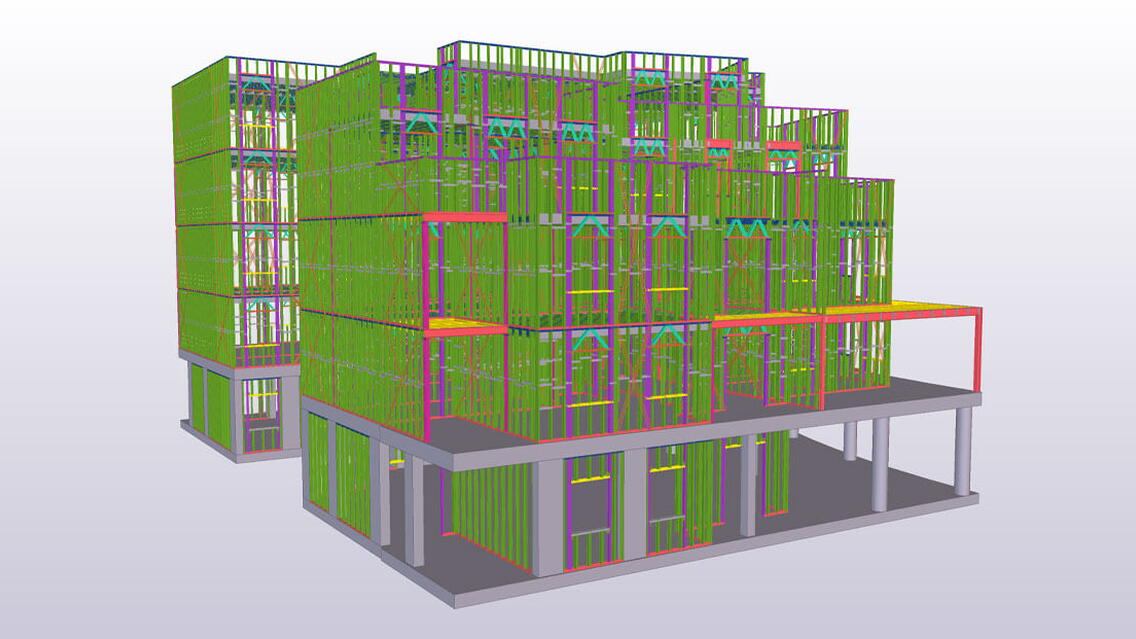

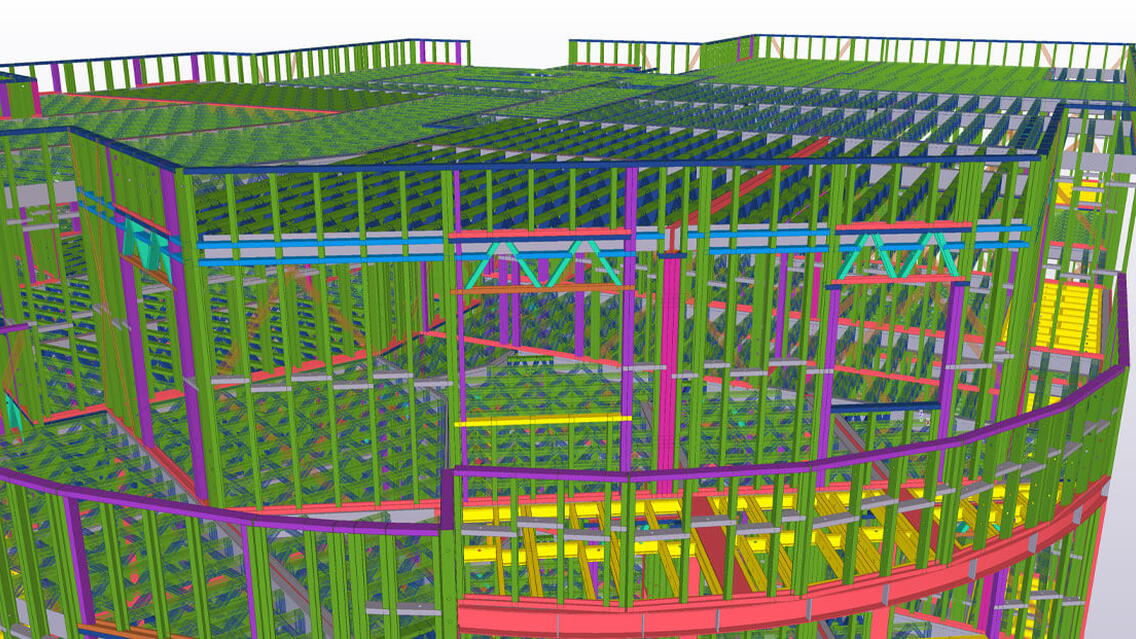

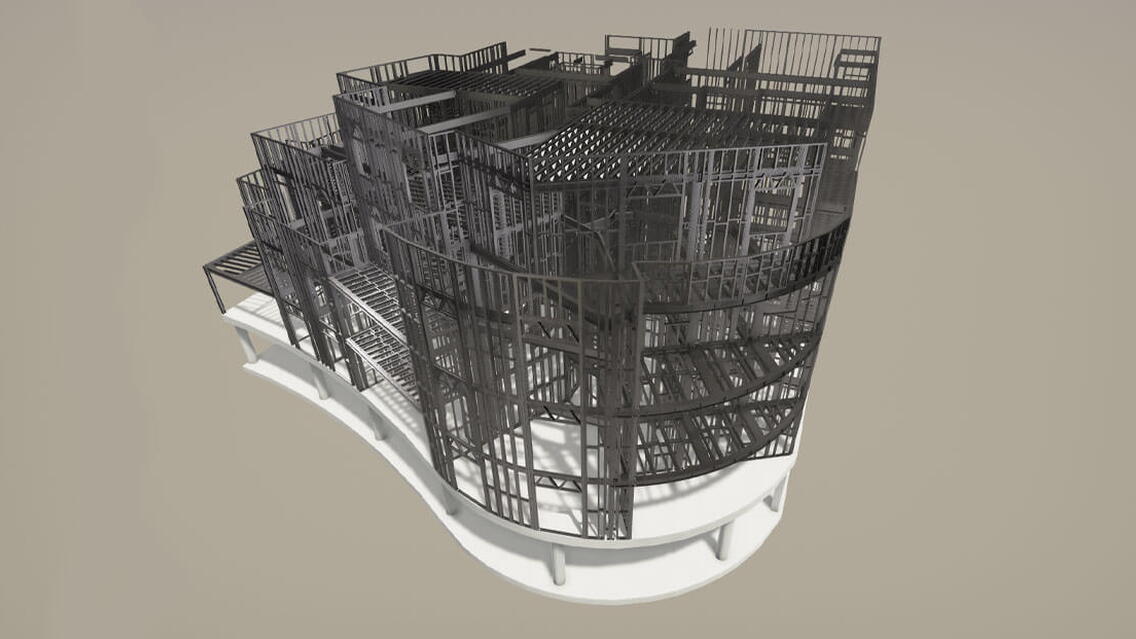

Croydon residential development 4 / 5 Storey SFS Load bearing structure from a hot rolled steel podium deck that was split over 2 levels the ground floor was SFS infill to the concrete frame. The building comprised of complexed curved balconies that were formed using hot rolled steel and SFS.

The ability and flexibility in being able to model in real time can only be delivered using Tekla Structures and implemented with the knowledge of the DACS design team.

What were the challenges and what made the project successful?

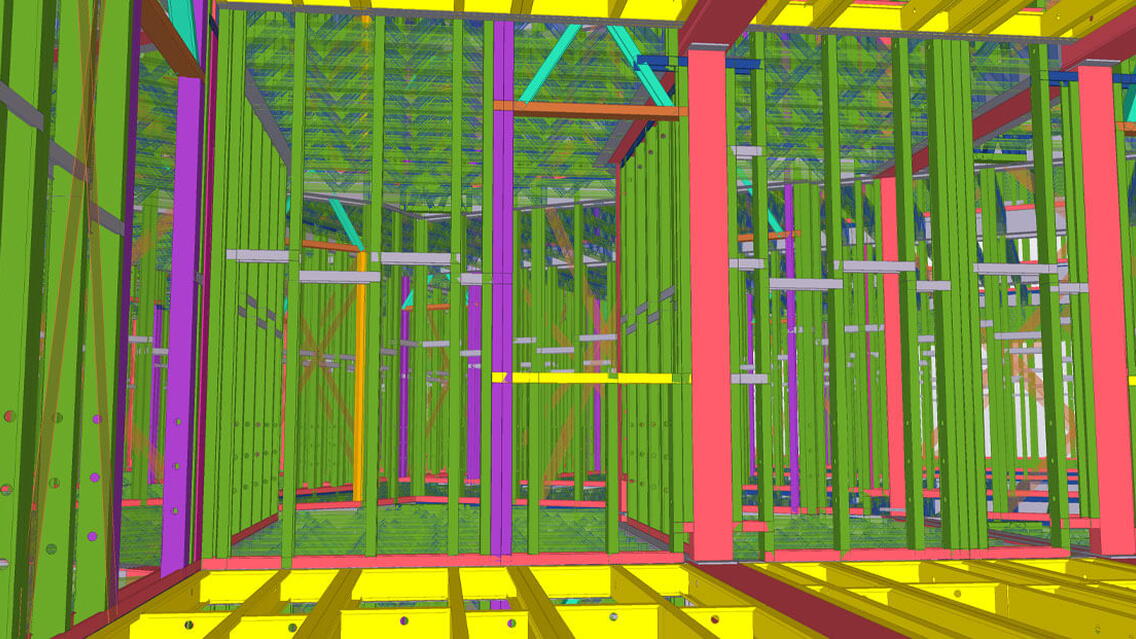

This Technical appraisal is used as a basis to start the SFS design in Tekla Structures and the structural engineering. As the model progresses, we issue to our structural engineer who then imports the model into Tekla Tedds. In the design process, we use various worksheets and guides to ensure all aspects of the design are captured using check lists and flow charts. As part of the continual development process in DACS we strive to drive efficiencies and reduce errors, these we record through each stage. These would be design errors, errors occurred in the release of the manufacturing data and errors raised on site. We then use toolbox talks or apply training were required to reduce or mitigate errors completely.

When the modelling process is started phasing and classes are used so that there is total control. This helps greatly with the abundant number of profiles, assemblies within the model environment if this approach was not implemented then trying to work your way around the model would be impossible. This detailed method of modelling is unparalleled when producing the drawing information for architectural sign off, the creation of site drawings and manufacturing packs. This goes in hand with the work ethic and ethos that is instilled within DACS.

Difficulties in modelling the curved/facetted areas and how these interfaces with beams and cassettes being square profiles.

What benefits utilizing BIM and Tekla software brought to the project?

Being able to extract data from the model such as assembly weights, total weights of profiles assists at site level this information can be added to the RAMS CDM. Frameclad using reports to procure materials so it can source prior to rolling. Efficiencies in manufacturing standard parts can be made by using reports generated. All frames entered onto the control sheets have the weights shown so that this identifies how heavy the frames are once they are assembled.

The project in numbers

From approval, the manufacturing data for all the assemblies was issued over a 5-week period to reflect Frameclad Limited production program. This includes both SFS and HRS fabrication data.